RYB Motion Solution brings advanced engineering and practical expertise to the metal processing industry, making complex machinery easy to understand for beginners and professionals alike. We offer reliable Coil Straightener solutions that ensure consistency, precision, and efficiency in production lines.

One such essential piece of equipment is the roller straightening machine, commonly known as coil straighteners. A coil straightener machine is designed to remove these imperfections and deliver flat, stress-free metal sheets ready for further processing such as cutting, punching, or forming. Modern coil straighteners are widely used in automotive, construction, appliance manufacturing, and fabrication units.

What Is a Roller Straightening Machine?

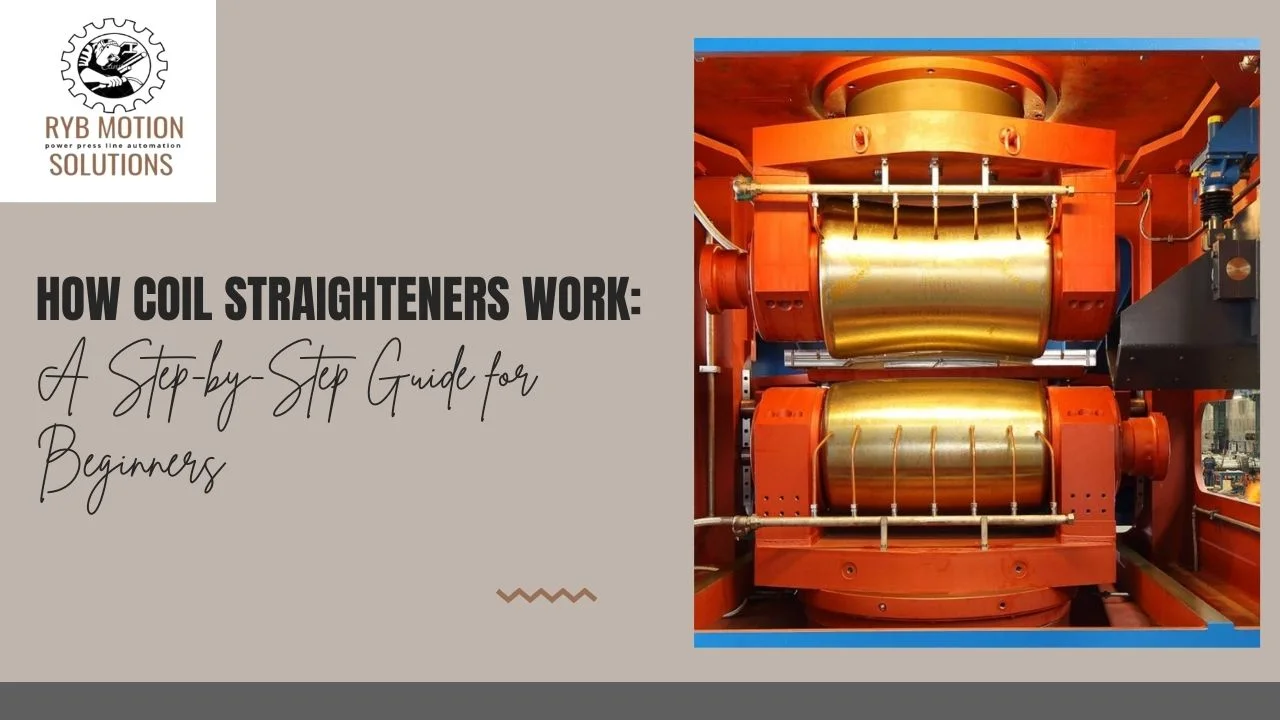

A roller straightening machine works on a simple yet effective principle: bending the metal slightly in opposite directions multiple times to eliminate unwanted curvature. The machine uses a series of precision-engineered rollers arranged in a specific configuration. As the metal strip passes through these rollers, it gradually becomes flat and uniform.

Unlike manual straightening methods, automated coil straighteners deliver faster output, consistent quality, and reduced material waste. This makes them ideal for both small workshops and large-scale industrial operations.

Also Read : Ultimate Guide to Plate Rolling : Process and Key Techniques

Step-by-Step Guide: How Coil Straighteners Work

Step 1: Loading the Coil

The decoiler holds the coil securely and feeds the strip into the coil straightener machine at a controlled speed. Proper alignment at this stage is important to avoid uneven straightening.

Step 2: Entry Guide and Feeding

Once the metal strip starts moving, it passes through entry guides. These guides ensure the strip enters the roller straightening machine centrally and smoothly. Accurate feeding prevents side bending and protects the rollers from uneven wear.

Step 3: Roller Adjustment

This is one of the most critical steps. The straightening rollers are adjusted based on the thickness, width, and material type of the coil. Upper rollers are typically adjustable, while lower rollers remain fixed.

Step 4: Progressive Bending Process

As the metal strip moves through the rollers, it is bent alternately upward and downward. This repeated bending goes slightly beyond the metal’s yield point, allowing it to relax into a flat shape. This is the core working principle of coil straighteners.

Step 5: Stress Relief and Flattening

By the time the strip exits the final rollers, internal stresses are evenly distributed. The result is a flat, straight metal sheet with improved dimensional accuracy. A well-calibrated coil straightener machine ensures minimal spring-back and consistent flatness.

Step 6: Exit and Further Processing

After straightening, the metal strip exits the machine and moves on to the next stage of production, such as cutting, stamping, or forming. Smooth integration with downstream equipment is another advantage of modern roller straightening machines.

Why Coil Straighteners Are Important for Beginners

For beginners in metal processing, understanding straightening is essential because flat material directly affects product quality. Poor straightening can lead to misalignment, defective parts, and material wastage. Using reliable coil straighteners helps beginners achieve professional results with less trial and error. RYB Motion Solution provides machines that are easy to operate, low in maintenance, and designed with safety features, making them suitable even for first-time users.

Applications of Coil Straightener Machines

A coil straightener machine is used across various industries, including:

- Automotive component manufacturing

- Sheet metal fabrication

- Electrical panel production

- Construction and infrastructure projects

- Appliance and furniture manufacturing

In all these sectors, the roller straightening machine plays a vital role in ensuring accuracy and efficiency.

Benefits of Using Modern Coil Straighteners

- Improved flatness and surface quality

- Reduced material waste

- Faster production cycles

- Consistent output for mass production

- Easy integration with automation systems

RYB Motion Solution continues to offer advanced straightening solutions that meet modern industry demands while remaining user-friendly.

Understanding how coil straighteners work is an important first step for anyone entering the metal processing industry. From loading the coil to stress-free flattening, every stage of the coil straightener machine is designed to improve material quality and production efficiency. A reliable roller straightening machine not only enhances finished products but also simplifies operations for beginners.

With its focus on innovation, quality, and ease of use, RYB Motion Solution offers dependable Roller Straightening Machine that supports businesses at every stage of growth. Whether you are just starting out or expanding your production line, investing in the right coil straightening technology can make a significant difference in your manufacturing success.