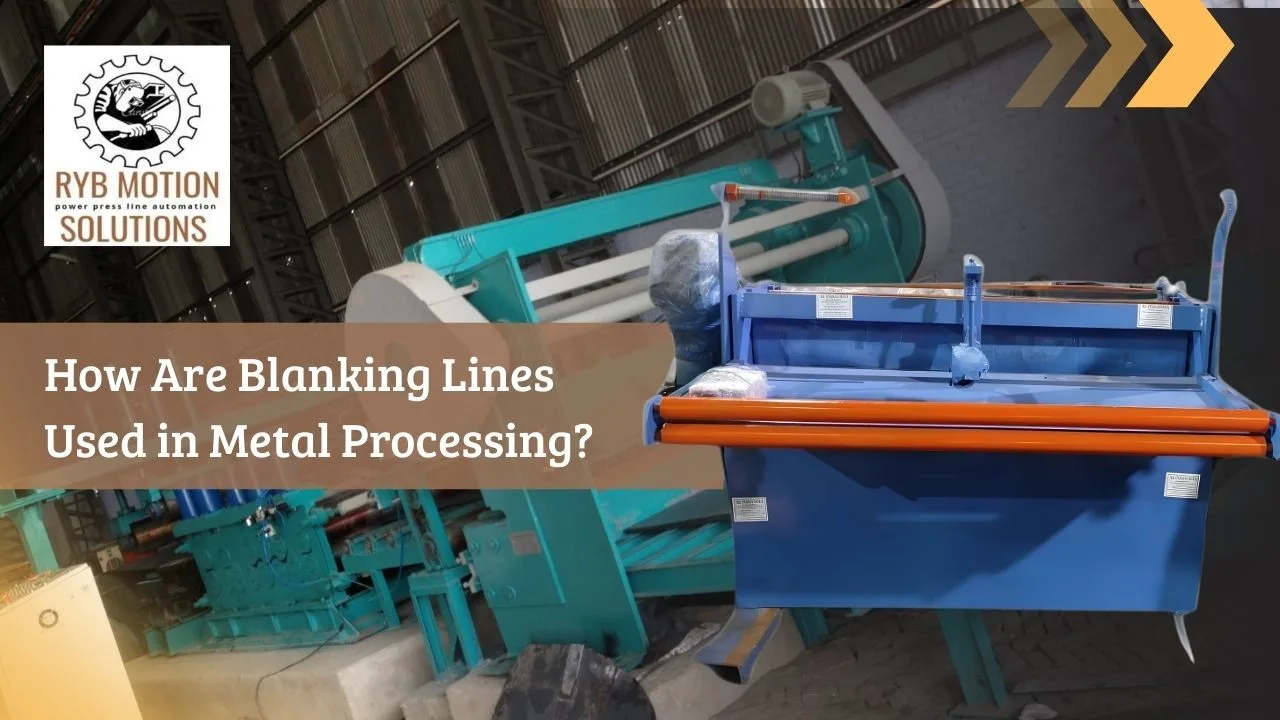

Ryb Motion Solution is a trusted name in the metalworking industry, we deliver advanced and reliable machinery for sheet metal processing. Among the many systems the company designs, installs, and maintains, the blanking line stands out as one of the most efficient and high-speed solutions used in modern manufacturing. With a commitment to innovation and precision, we continue to offer cutting-edge technology that simplifies metal fabrication and improves overall productivity.

How Are Blanking Lines Used in Metal Processing?

A blanking line is a fully automated system designed to cut flat pieces known as blanks from large metal coils. These blanks are then used to manufacture various components for automotive, electrical, industrial, and appliance industries. A blanking line works by unwinding a metal coil, flattening it, feeding it into precision tooling, and punching out the required shape. The result is a high-quality metal blank that becomes the foundation for further manufacturing processes such as stamping, bending, or forming. Ryb Motion Solution ensures each machine is engineered with precision so that clients can achieve maximum accuracy and consistency in their production operations.

Components of a Blanking Line

A typical Auto Blanking Line includes the following major components:

- Decoiler: The decoiler holds the metal coil and unwinds it at a controlled speed. It ensures smooth feeding without damaging the sheet.

- Straightener or Leveler: This unit removes coil-set, waves, or bends from the sheet, ensuring a perfectly flat piece before cutting.

- Feeder: The feeder pushes the metal sheet into the cutting tool with precise measurements. Accuracy in feeding ensures uniform blanks.

- Blanking Press: This is the heart of the blanking line. The press uses a high-pressure die to cut the metal into the required shape with clean, sharp edges.

- Stacking Unit: After cutting, the finished blanks are neatly stacked and collected for the next stage of production.

With these synchronized components, an Auto Blanking Line ensures high-speed, consistent, and error-free production.

Applications of Blanking Lines in Metal Processing

Blanking lines are widely used in industries that demand precision and repetitive cutting. Their main applications include:

- Automotive manufacturing (car doors, roof panels, structural parts)

- Electrical appliances (panels, casings, enclosures)

- HVAC industries

- Sheet metal fabrication workshops

- Furniture and lighting industries

- Aerospace and defense components

Whether it’s a simple rectangular blank or a highly engineered shape, blanking systems play an essential role in generating accurate raw materials for further processing.

Also Read : Uncoiling Excellence: The Ultimate Guide to Hydraulic Decoiler Machines in Advanced Manufacturing

Advantages of Using a Blanking Line

- High Productivity: Blanking lines operate continuously at high speeds, allowing manufacturers to produce thousands of blanks per hour.

- Consistent Quality: Because the process is automated, each blank maintains the same dimension, thickness, and edge quality.

- Reduced Wastage: Precise cutting reduces scrap and material loss, making the process cost-efficient.

- Lower Manpower Requirement: Automation reduces the need for manual labor, minimizing errors and improving safety.

- Versatility: From thin sheets to thicker coils, blanking lines handle a wide variety of metals including steel, aluminum, copper, and stainless steel.

- Improved Safety: Modern blanking lines include sensors, protective guards, and automated feeding systems that reduce human-machine interaction.

Ryb Motion Solution: Your Trusted Partner for Metal Processing Machines

At Ryb Motion Solution, every blanking line is built with careful engineering, premium components, and strict quality control. Our company focuses on ensuring long-term durability, smooth operation, and energy-efficient performance. Whether you require a high-speed blanking system for automotive production or a compact design for general fabrication, Ryb Motion Solution is committed to fulfilling your requirements with precision and professionalism. We also provide installation, maintenance, customization, and after-sales support to ensure the machine runs at optimal performance throughout its lifespan.

Blanking lines are essential equipment in the metal processing industry, providing accuracy, speed, and consistency in producing metal blanks. With advanced features, automation, and reliable engineering, they have transformed the way manufacturing units operate. We ensure that industries receive high-performing solutions tailored to their needs. With a focus on innovation and customer satisfaction, our company continues to provide world-class machinery that enhances productivity and supports long-term growth.